Our company has implemented international advanced technologies with high automation in melting and casting aluminum bars, mould development, profile extrusion, sandblasting, anodic oxidation, simple and complex salt coloring, electrophoresis coating, powder spraying, fluorine carbon spraying, energy-conservation heat insulation aluminum profile and even precise inspections that the product quality reach international leading level.

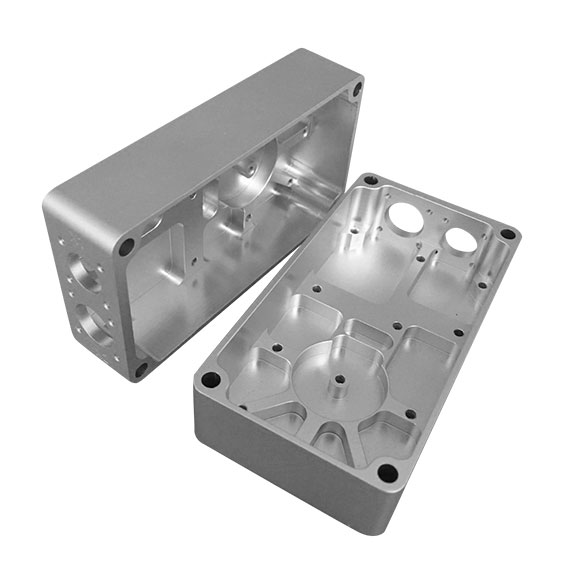

| Item | CNC ALUMINIUM |

| Material | 6000 series Aluminum, 7000 series Aluminum |

| Temper | T3, T4, T5, T6, T7, T8 |

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. |

| Shape | square, round, rectangular, customized |

| Application | In furniture, windows& doors, decorations, industry, construction, etc. |

| Surface treatment | Wood grain, Brushed, powder coating, electrophoresis, anodized and etc. |

| Colors | Ref powder coating color sheet and customized color available |

| Deep process | CNC, drilling, milling, cutting, welding, bending, assembling |

| MOQ | 500kgs for each aluminum profile, CNC Aluminum (According to actual communication) |

| Packing Details | (1) Inside: packed with plastic protective film to protect each piece |

| (2) Outside: Wrap to be bundles by waterproof craft paper | |

| Delivery time | (1)Die Developing and Sample testing: 12-18 days . |

| (2) Mass Production completed: 10-30days after sample is confirmed by Buyer. | |

| Production capacity | Can totally support customer’s demands. |