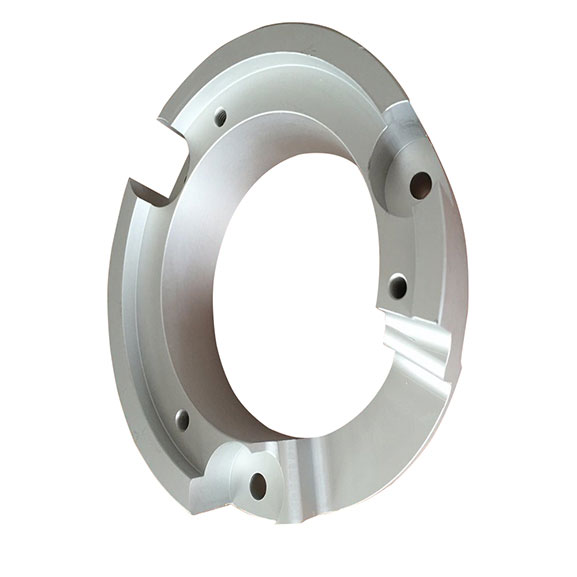

Advantages of Our CNC Milling/Turning Aluminum Components

– Full inspection throughout the whole CNC aluminum parts production

– Rapid prototyping and different amounts of manufacturing experiences

– Professional technical and engineering team support

– Cost-effective prices and strict quality management system

| Product Type | CNC turning, milling, drilling, grinding, wire EDM cutting etc. |

| Our Services | CNC Machining, Plastic Injection, Stamping, Die Casting, Aluminum Extrusion, Mould Making, etc |

| Material | Aluminum, Brass, Stainless Steel, Copper, Plastic, Wood |

| Surface Treatment | Anodizing, Sandblasting, Painting, Powder coating, Plating, Silk Printing, Brushing, Polishing, Laser carve, Engraved |

| Service Project | To provide production design, production and technical service, mould development and processing, etc |

| Drawing Format | PRO/E, Auto CAD, Solid Works, CAD/CAM/CAE |

| Testing Machine | Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

| Industry used | Machinery; heavy duty equipment; electronic device; Auto spare parts; optical telecommunication |

| Usage | Architectural applications, extrusions, window frames, door frames, roofs, and sign frames, shop fittings, tubes, etc. |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

| Delivery time | 7-30 days after receive the pre-payments |

| Applications | Electronic, auto, electric appliance, electrical machine, toy, medical treatment, furniture and fitness equipment and other industries. |