August 26th 2021

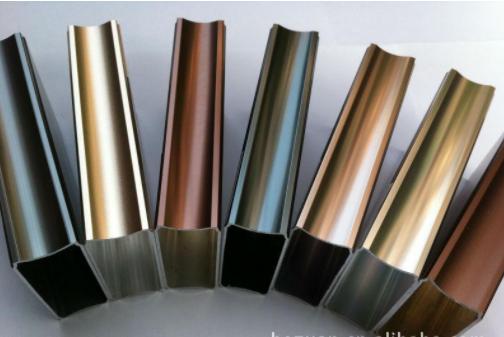

Metal finishing or metal finishes, is the process of utilizing different techniques to alter the surface of an object, for improving the appearance and properties like corrosion resistance, tarnish resistance, chemical resistance, wear resistance, and hardness, modifying electrical conductivity, removing burrs or applying specific colors to the machined components. It usually through adding a layer of metal or non-metal coating on the exterior of a metallic workpiece, which can also clean the part at the same time. The metal surface finishing services commonly applied on various CNC machining parts made of aluminum, stainless steel, brass and more materials.

Benefits of Metal Finishing Process

The functions of metal surface treatment can be summarized as follows:

– Improve the appearance

– Add specific beautiful colors

– Change the luster

– Enhance chemical resistance

– Increase wear resistance

– Limit effects of corrosion

– Reduce friction

– Remove surface defects

– Cleaning the parts

– Serve as a primer coat

– Adjust the sizes

Do you want your CNC parts to be more corrosion-resistant or get a specific look? .bftprecision Metal finishing service is an essential choice to achieve your design perfectly. .bftprecision is an accomplished finished parts manufacturer, our workers and craftsman are capable to provide precision CNC machining services and a wide range of finishing services including aluminum anodizing, painting, passivation, electroplating, powder coating, polishing, black oxide, conversion coating, abrasive blasting, etc. Here are the introductions to different types of metal finishes, more details please feel free to contact us.

How to choose surface finishing

If the customer is super-rich, of course, he can choose any surface treatment method he wants. If the customer lives in the real world, he needs to choose a surface treatment method with good cost and effect according to local conditions.

When determining the surface treatment method of the part, the function, cost, and aesthetics of the part must be considered as the standard.

Among these three factors, the function is the most important. It is necessary to consider how the surface treatment affects the strength of the material, how the durability of the material surface limits the surface treatment, and establish the applicable tolerance type. Followed by cost and appearance.

Through the analysis of product components, the treatment method of each surface can be determined. Contact bftprecision and the engineers will answer all the questions customers have.

What can bftprecision provide?

BFT has a variety of equipment and trusted partners, which can achieve various surface treatments customers need. If the customer is hesitant to choose between various surface treatments, BFT engineering team can analyze the product design and customize an economical surface treatment under the premise of achieving the effect.

BFT can provide product development solutions and rapid prototyping according to customer needs and can provide multiple services such as turning, milling, and surface grinding.

BFT will serve customers in every process of realizing customer ideas.