August 26th 2021

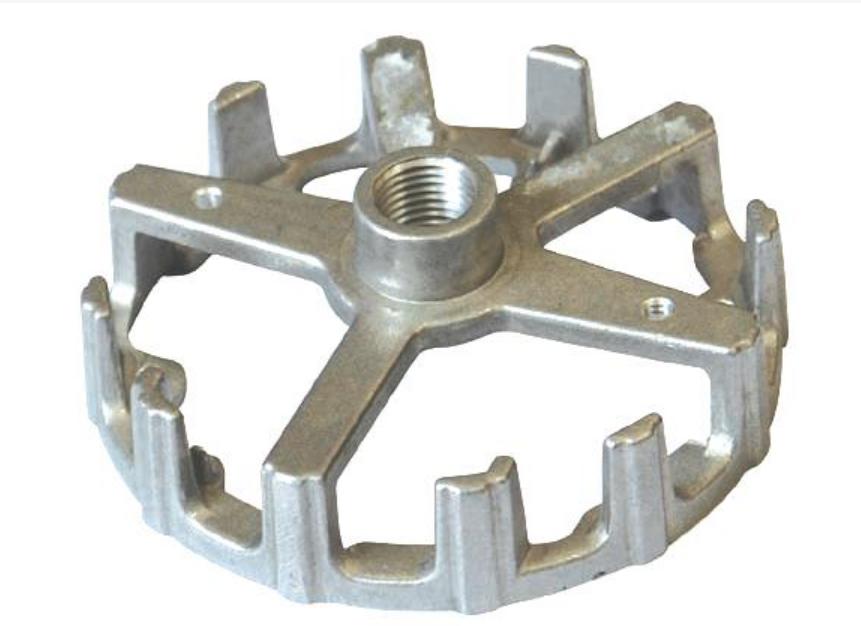

Die casting die is a tool for casting metal parts, a tool for completing the die casting process on a special die casting die forging machine. The basic process of die casting is that the liquid metal is first cast at low or high speed and filled into the cavity of the die. The die has an active cavity surface, which is forged under pressure along with the cooling process of the liquid metal, not only to eliminate the shrinkage cavity and porosity defects of the blank, but also to make the internal structure of the blank reach the forged broken grain. The comprehensive mechanical properties of the blank are remarkably improved.

Chinese name

Die casting mould

Foreign names

Die casting mould

This mass

A method of liquid die forging

The technological process

The liquid metal is first cast at low or high speed

Three main factors

Die casting material, die casting machine,

Die casting material, die casting machine and die are the three main elements of die casting production. The so-called die casting process is to use these three elements organically and comprehensively, so that it can produce qualified castings with good appearance, internal quality, size conforming to the requirements of the drawing or the agreement steadily and efficiently, or even high quality castings.

The alloy used in die casting is mainly non-ferrous alloy, as for the ferrous metal (steel, iron, etc.) due to the problems of mold materials, less use. In the non-ferrous alloy die casting, aluminum alloy is widely used, followed by zinc alloy. Here is a brief introduction to die – casting nonferrous metals.

(1) the classification of die casting non-ferrous alloy is blocked mixed contraction free shrinkage lead alloy – 0.2-0.3-0.4-0.4% and 0.5% 0.3% low melting point alloy tin alloy zinc alloy — — — — — — — – 0.3-0.6-0.4-0.6% 0.4% and 0.8% Al-si series 0.7 0.5-0.3-0.5% – 0.7% – 0.9% of die casting non-ferrous alloy aluminum alloy aluminum bronze series aluminum magnesium – 0.5-0.7-0.9-0.9% and 1.1% 0.7% high melting point alloy aluminum zinc series magnesium alloys — — — — — — — — — – 0.5-0.7-0.9% 0.7% 0.9 1.1% of copper alloy

(2) The recommended casting temperature for all kinds of die casting alloys: the average wall thickness of castings of alloy types is less than or equal to 3mm, the average wall thickness of castings > 3mm simple structure complex structure simple structure complex structure

Aluminum alloy aluminum silicon series 610-650℃ 640-680℃ 600-620℃ 610-650℃

Aluminum copper system 630-660℃ 660-700℃ 600-640℃ 630-660℃

Aluminum magnesium series 640-680℃ 660-700℃ 640-670℃ 650-690℃

Aluminum and zinc series 590-620℃ 620-660℃ 580-620℃ 600-650℃

Zinc alloy 420-440℃ 430-450℃ 400-420℃ 420-440℃

Magnesium alloy 640-680℃ 660-700℃ 640-670℃ 650-690℃

Copper alloy common brass 910-930℃ 940-980℃ 900-930℃ 900-950℃

Silicon brass 900-920℃ 930-970℃ 910-940℃ 910-940℃

* Note: ① The casting temperature is generally measured by the temperature of the liquid metal in the holding furnace.

(2) The casting temperature of zinc alloy should not exceed 450℃ to avoid coarse grains.

The design process

Edit the voice

1, according to the type of materials used in the product, product shape and precision and other indicators of the product process analysis, determine the process.

2. Determine the placement of products in the mold cavity, analyze and design the parting surface, drainage system and pouring system.

3. Design the assembling and fixing modes of the core of each activity.

4. Design of core-pulling distance and force.

5. Design of ejection mechanism.

6. Determine the die casting machine, and design the die frame and cooling system.

7. Check the relative dimensions of molds and die casting machines, and draw the process drawings of molds and various parts.

8. Design completion [1].

Frequently Asked Questions

The control of the surface temperature of die casting die is very important for the production of high quality die castings. Uneven or inappropriate die casting temperature can also lead to unstable casting size and deformation of the casting during the production process, resulting in defects such as thermal pressure, sticking mold, surface sag, internal shrinkage cavity and hot bubble. When the mold temperature is different, the variables in the production cycle, such as filling time, cooling time and spraying time, will be affected to different degrees.

1). Cold lines:

Reason: the temperature of the front end of melting soup is too low, and there are traces of overlapping

Improvement methods:

1. Check if the wall thickness is too thin (design or manufacture), thinner areas should be filled directly

2. Check that the shape is not easy to fill; Too far away, closed areas (e.g., fin, bulge), blocked areas, too small fillet, etc., are not easy to fill. And watch for ribs or cold spots

3. Shorten the filling time, shorten the filling time method

4. Change filling mode

5. Methods of increasing mold temperature

6. Raise the temperature of the soup

7. Check alloy composition

8. Expanding the escape route may help

9. A vacuuming device may be useful

2). Crack:

The reason:

1. Shrinkage stress

2. Cracked under pressure on ejection or entire edge

Improvement methods:

1. More rounded corners

2. Check whether there is a hot spot

3. Pressurization time change (cold chamber machine)

4. Increase or shorten mold closing time

5. Increase the drawing Angle

6. Add the ejection pin

7. Check whether the mold is misplaced or deformed

8. Check alloy composition

(3). Porosity:

The reason:

1. Air is mixed in the soup

2. Gas source: melting, in the pipe, in the mold, release agent

Improvement methods:

1. Slow down

2. Check if the runner turns smoothly and the cross-sectional area is decreasing

3. Check to see if the area of the escape duct is large enough, if it is obstructed, and if it is located at the last filling place

4. Check whether the release agent is sprayed too much and the mold temperature is too low

5. Use the vacuum

4). Cavitation erosion:

Cause: Due to the sudden decrease of pressure, the gas in the melting soup suddenly expanded, impacting the mold and causing mold damage

Improvement methods:

The cross-sectional area of the flow channel should not change sharply

5). Shrinkage cavity:

Reason: When a metal solidifies from a liquid state to a solid state, the space occupied by the metal becomes smaller. If there is no metal supplement, shrinkage cavity will form, usually at a slower solidification place

Improvement methods:

1. Increase the pressure

2. Change the mold temperature. Local cooling, spray type agent, reduce mold temperature. Sometimes just change the location of the shrinkage hole, rather than the shrinkage hole

6). Peeling:

The reason:

1. Poor filling mode, resulting in melting soup overlap

2. Mold deformation, resulting in melting soup overlap

3. Inclusion oxide layer

Improvement methods:

1. Switch to high speed early

2. Shorten filling time

3. Change filling mode, gate position, gate speed

4. Check mold strength is sufficient

5. Check whether the pin and die devices are in good condition

(6. Check for inclusion of oxide layer

7). Bellows:

Reason: The first layer of melting soup cools rapidly on the surface, while the second layer of melting soup flows through and fails to melt the first layer, but it has enough fusion to cause different tissues

Improvement methods:

1. Improved filling mode

2. Shorten filling time

8). Holes caused by poor flow:

Cause: The soup flows too slowly, or is too cold, or the filling pattern is poor, so there are holes in the solidified metal joints

Improvement methods:

1. The same method of improving cold stripe

2. Check whether the temperature of the melting soup is stable

3. Check whether the temperature charge of the mold is stable

9). Hole in parting surface:

Cause: It could be shrinkage or blowhole

Improvement methods:

1. In case of shrinkage, reduce the thickness of gate or overflow inlet

2. Cooling gate

3. If there are air holes, pay attention to exhaust or air trapping

10). Flash:

The reason:

1. Clamping force is insufficient

2. Bad mold closing

3. Insufficient die strength

4. The soup is too hot

11). Shrinkage in:

Cause: Shrinkage occurs below the pressure surface

Improvement methods:

1. Methods to improve shrinkage cavity

2. Local cooling

3. Heat the other side

12). Carbon deposition:

Cause: release agent or other impurities accumulated on the mold.

Improvement methods:

1. Reduce the amount of release agent spray

2. Higher mold temperatures

3. Select suitable release agent

4. Use soft water to dilute the release agent

13). Bubble:

Reason: The gas is trapped under the surface of the casting

Improvement methods:

1. Reduce air entrapment (same as air hole)

2. Cool or prevent low mold temperature

14). Sticky mode:

The reason:

1. Zinc accumulates on the surface of the die

2. Melt soup impact mold, resulting in mold surface damage

Improvement methods:

1. Reduce mold temperature

2. Reduce surface roughness

3. Increase the drawing Angle

4. coating

5. Change filling mode

6. Reduce gate speed [1]

The latest technology

Edit the voice

A variety of new surface treatment technologies for die casting die continue to emerge, but in general, it can be divided into the following three categories:

(1) Improvement of traditional heat treatment process;

(2) Surface modification technology, including surface thermal diffuser treatment, surface phase transformation strengthening, electric spark strengthening technology, etc.;

(3) Coating technology, including electroless plating, etc.

Die casting mold is a large category of mold. With the rapid development of automobile and motorcycle industry in China, the die casting industry has ushered in a new period of development. At the same time, higher requirements have been put forward for the comprehensive mechanical properties and life span of die casting die. Luo Baihui, secretary-general of the International Mold Association, believes that it is still difficult to meet the needs of constantly improving performance only by relying on the application of new mold materials. It is necessary to apply various surface treatment technologies to the surface treatment of die casting molds in order to meet the requirements of high efficiency, high precision and high life of die casting molds. Among all kinds of molds, the working conditions of die-casting molds are relatively harsh. Die casting is to make the molten metal in high pressure, high speed under the mold cavity and die casting molding, in the process of working repeatedly with hot metal contact, so the die casting mold has high heat fatigue, thermal conductivity wear resistance, corrosion resistance, impact toughness, red hard, good release, etc.. Therefore, the die – casting die surface treatment technology requirements are high.

1. Improvement technology of traditional heat treatment process

The traditional heat treatment process of die casting mold is quenching and tempering, and then the surface treatment technology has been developed. Due to the variety of materials that can be used as die casting molds, the same surface treatment technology and process can produce different effects on different materials. Shikoff proposed the substrate pretreatment technology for the substrate and surface treatment technology of the die, and proposed suitable processing technology for different die materials on the basis of traditional process, so as to improve the performance of the die and improve the life of the die. Another development direction of heat treatment technology improvement is to combine traditional heat treatment technology with advanced surface treatment technology to improve the service life of die casting die. Such as the chemical heat treatment method of carbonitriding, combined with conventional quenching and tempering process of NQN (namely the carbonitriding, quenching and carbonitriding composite reinforcement, not only get high surface hardness, and the effective depth of hardening layer increase, rational distribution of carbonitriding layer hardness gradient, tempering stability and corrosion resistance, so as to make the die casting mould in good heart department performance at the same time, Surface quality and performance are greatly improved.

2. Surface modification technology

Surface thermal diffusing technology

This type includes carburizing, nitriding, boronizing and carburizing, sulfur-carburizing, etc.

Carburizing and carbonitriding

Carburizing process is applied in cold, hot and plastic mold surface strengthening, can improve the life of the mold. Such as 3Cr2W8V steel die casting die, first carburizing, and then by 1140 ~ 1150℃ quenching, 550℃ tempering twice, the surface hardness can reach HRC56 ~ 61, the die life of die casting non-ferrous metals and their alloys can be increased 1.8 ~ 3.0 times. When carburizing, the main process methods are solid powder carburizing, gas carburizing, and vacuum carburizing, ion carburizing and carburizing formed by adding nitrogen in the carburizing atmosphere. Among them, vacuum carburizing and ionic carburizing is the technology developed in the last 20 years, the technology has the characteristics of fast infiltration, uniform infiltration layer, gentle carbon concentration gradient and small workpiece deformation, will play a more and more important role in the surface of the die, especially in the surface treatment of precision die.

Nitriding and related low temperature thermal diffusing technology

This type includes nitriding, ion nitriding, carnitriding, oxygen nitriding, sulfur nitriding and sulfur-carbon nitriding, oxygen nitriding and sulfur ternary nitriding methods. These methods have the advantages of simple processing process, strong adaptability, low diffusing temperature of 480 ~ 600℃, small deformation of the workpiece, especially suitable for the surface strengthening of precision die, and the nitriding layer has high hardness, good wear resistance and good adhesion resistance.

The service life of 3Cr2W8V steel die casting die after quenching and tempering and nitriding at 520 ~ 540℃ can be increased by 2 ~ 3 times compared with that of the die without nitriding. Many die casting moulds made of H13 steel in the United States are nitriding and nitriding instead of one tempering. The surface hardness is as high as HRC65 ~ 70, and the hardness of the die center is low and the toughness is good, so as to obtain excellent comprehensive mechanical properties. Nitriding process is a common process for surface treatment of die casting die. However, when the nitriding layer has a thin and brittle white layer, it cannot resist the effect of alternating thermal stress, and it is easy to produce microcracks and reduce the thermal fatigue resistance. Therefore, in the nitriding process, the process should be strictly controlled to avoid the generation of brittle layer. The secondary and multiple nitriding processes are proposed abroad. Repeated nitriding can decompose the nitride white layer, which is easy to produce microcracks during service, increase the thickness of nitriding layer, and at the same time make the die surface with very thick residual stress layer, so that the life of the die can be significantly improved. In addition, salt bath carburizing and salt bath sulfur-nitrogen carburizing are also used. These processes are widely used in foreign countries, but rarely seen in China. For example, the TFI+ABI process is impregnated in the alkaline oxidation salt bath after the salt bath nitrogen carburizing. The surface of the workpiece oxidizes and turns black. The wear resistance, corrosion resistance and heat resistance are improved. The life of die casting die of aluminum alloy treated by this method is increased by hundreds of hours. For example, the Oxynit process developed in France, which is nitriding after sulfur-nitrogen carburizing, is more characteristic when applied to non-ferrous metal die casting mold.

Industry status quo

Edit the voice

Domestic die casting mold status

China’s die casting mold industry is developing rapidly, the total output growth is obvious, the total output of domestic die casting mold is second only to the United States, has jumped to the second place in the world, become a real die casting country. Can have such achievements mainly from China with a vast advantaging market and relatively low resources and labor advantages, has been very obvious cost performance in the international die casting trade market occupies a large advantage, according to the situation, the future of China’s die casting industry development prospects are very broad.

Although China’s die casting mold in the “eleventh five-year” period had a major breakthrough. However, its international visibility is still low ranking, production is also increasing but most of the die casting mold is only for domestic demand. Due to technical constraints, the quality is difficult to break through, and some large domestic demand enterprises also frequently extend olive branch to foreign die casting die enterprises, serious trade deficit makes it difficult for domestic die casting enterprises to move forward.

International die casting mold status

In the context of increasingly fierce competition in the international die casting die market, the Japanese die casting die industry is also trying to reduce production costs. In terms of the size of the market, the decline in both output and domestic demand was most pronounced in Japan. Japanese die manufacturers pay more attention to polishing and grinding process in technology, while German die manufacturers start by improving the precision and efficiency of machining and discharge machining to reduce the time of manual processing. The Japanese die casting die industry is gradually shifting the die with low technical content to the region with low labor cost, and only producing the product with high technical content in Japan. The trend of Accelerating the transfer of Japan to foreign countries makes the use of die casting die in Japan reduce.

Analysis of factors influencing the development of die casting die industry in China

The main reasons for restricting the development of China’s die casting die industry are as follows: first, there are still many shortcomings in the use of raw materials in domestic die casting die; Second, the backwardness of technology, is the development of China’s die casting die industry has been very big obstacles; Third, the supporting system of China’s die casting die industry is not perfect.

The industrial development Edit the voice

New alloy die casting die products sell well in China, but this phenomenon does not mean that the sales are very good in the world, foreign market demand is often different from domestic. According to relevant experts, there are three main reasons for restricting the export of Chinese die casting moulds. First, there are still many shortcomings in the use of raw materials in domestic die casting moulds; Second, technological backwardness is also one of the obstacles to the development of China’s die casting die industry; Third, the supporting system of China’s die casting die industry is not perfect. These are the bottlenecks that restrict the development of China’s die casting die industry. Only when China’s die casting die industry breaks through these bottlenecks, its share in the international market will be greatly improved.

Die casting and mould have distinction to have connection again already, the birth of the die-casting mould industry is both the most perfect combination, in other words, die casting, mold, die-casting mold is three different industries, its relations mainly exist in several ways: integration of die casting, mold, mould manufacturing, and rarely give other companies do mould; Professional die casting mold manufacturing, no die casting; Only die casting, no die making capacity. With the intensification of industrial division of labor, the gradual blurring of industrial boundaries and the development of industrial crossover, the three industries should strengthen the connection, learn from each other, integrate the three industries, and exist in the form of “integration”. It is believed that China’s die casting mold industry will usher in more and greater development opportunities and space [1].