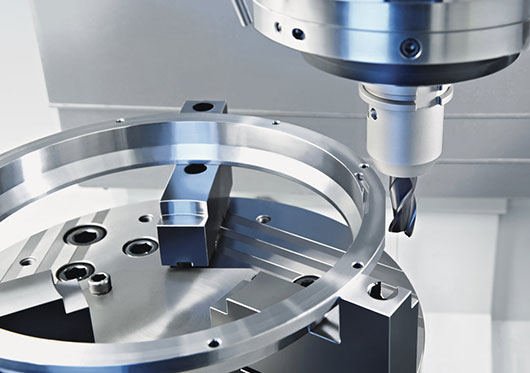

Drilling is the cutting process in which the workpiece does not move, making the cutter move, aligning the cutter center with the hole center, and making the cutter rotate. CNC Drilling is primarily done on CNC machines including CNC milling machines and lathes. CNC drilling service produces round holes, typically for machine screws and bolts. Drilling can process CNC drilling parts with metals, hard plastics, wood and most other rigid materials. There are several types of drilling machines available for CNC, including these drill presses: Upright, Bench and Radial. When in use, the step-by-step process for CNC drilling includes:

Bellflower provides best CNC drilling services for the fabrication of both small and large series of parts of any complexity. We use various types of CNC drilling machines including upright, bench, radial, which allows us to drill holes of both simple and complex patterns up to 7 cm in diameter. The CNC drilling parts be made of metals and alloys (aluminium, steel, copper and others) and polymers. Our drilling services provide us with the capability to complete your job in-house to our exacting quality standards. Our advanced CNC drilling equipment is integrated with our machining centers and allows us to efficiently and precisely drill your part, whether you require simple or complex drilling patterns. Our drilling services offer precision machining for complex shapes that meet all your requirements.

Accuracy:

The precision offered by CNC is unmatched. It has provided companies in all industries with many returns, including raised productivity, lowered expenses and optimized production lines.

Versatility:

It’s a significant advantage that CNC drilling machines are capable of accepting multiple bits. While operators may need to use a different type of drilling machine, they can equip that machine with a series of bits. Some machine types include a tool turret for even faster shuffling between bits.

Reproducibility:

A continuous challenge for companies across markets is producing identical batches of products. This hurdle becomes amplified for custom machining projects. With CNC, however, those challenges are solved, leading to a consistent, imperfection-free production line.

Increase your capacity

Shorten your lead times

Improve the quality & accuracy of your product

Reduce installation time

Offer more complex designs

Along with our CNC machining services, you can opt for a wide selection of metal surface finishing services for your CNC drilling parts to improve the parts appearance, surface smoothness, corrosion resistance and other performance.

![]() Contact Personal:Jenny xia

Contact Personal:Jenny xia

![]() +86-13430452816

+86-13430452816

![]() whatsapp: 86-13430452816

whatsapp: 86-13430452816

![]() Jenny.xia@bellflower.com.cn

Jenny.xia@bellflower.com.cn

![]() Contact Personal:Claire Wang

Contact Personal:Claire Wang

![]() +86-17704089596

+86-17704089596

![]() whatsapp: 86-18807425347

whatsapp: 86-18807425347

![]() Claire.wang@bellflower.com.cn

Claire.wang@bellflower.com.cn

![]() Contact Personal:James ye

Contact Personal:James ye

![]() +86-13723765257

+86-13723765257

![]() whatsapp: 86-13723765257

whatsapp: 86-13723765257

![]() James@bellflower.com.cn

James@bellflower.com.cn

![]() 2F,Building A, Zhongxing science Park, No. 8, Xinhe Blvd, Xinqiao Str, BaoAn Dist,ShenZhen,GD,CNH.

2F,Building A, Zhongxing science Park, No. 8, Xinhe Blvd, Xinqiao Str, BaoAn Dist,ShenZhen,GD,CNH.

Copyright © 2021 All Rights Reserved.

We will call you back soon